Bearings

For our race car we used ceramic bearings as they appear to contain the lowest rolling resistance and are the most lightweight out of all the bearings we could choose from. After receiving the bearings, we tested them under controlled environments and found that bearings with a smaller diameter, both inside and out, worked better than those with a bigger diameter. After the testing, we have decided to use the smallest type of bearing we could find, and invented a way to attach the bearing to the main body of the car which keeps the bearing in place but allows the outer layer of the wheel to roll freely.

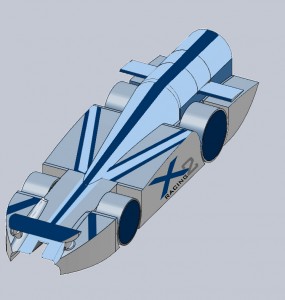

Wheels

What appears to be the wheels on the design are not actually the wheels themselves. They are a sort of inner layer for the wheel that is joined to the main body and does not actually rotate during the racing process. On the outer ends of such “wheels” are holes that the bearing we chose can fit exactly into. Then, the outer layer of the wheel is attached to the bearing and that outer layer wheel spins as the CO2 canister boosts the car forward. The outermost layer of the wheel, i.e. the tire, is a thin layer of carbon fiber that is lightweight and theoretically will help increase the speed of the car.

Main Body

The main body is made according to the rules and guidelines. The body consists of three main parts – the middle body, the skirts (on either side) and the CO2 canister holder. The middle body is a thin layer with the tether line slot on the bottom face and the CO2 canister holder on the other end. The shape of the middle body has been developed and tested as much as 20 times alone to ensure that the middle body is as aerodynamic as it can be. The skirts on either side of the car, joined to the middle body, effectively directs air away from the wheels in an aerodynamic manner. Their primary purpose is to decrease the drag caused by the wheels, and when designing our design engineers have incorporated understanding on the airfoil (the teardrop shape) when creating and testing the shapes they have come up with. The CO2 canister holder incorporates the same ideas – the most aerodynamic shape out of all our brainstorm of ideas, proven by numerous cycles of development, testing, feedback and development conducted by our design engineers.

Wings

When designing the car, we try to follow the rules and guidelines as much as possible, and so we have developed two wings – one on the front and one at the back – to fit onto the car. To make our manufacturing process faster and simpler, our team has researched and discussed various solutions and finally came upon the idea of having the wings made separately and assembled together in the end. Both wings rely on a simple design rule – low drag. Taking a side view of either wing, a resemblance to the airfoil would be clearly seen. The wings have also undergone a few ten testings before our team of designers found the most aerodynamic pair, and found a way to assemble them together onto the car during the manufacturing process, in collaboration with the manufacturer.

The front wing is inserted vertically into the body of the car through the two holes situated on the front side skirts. The front wing itself, however, consists of a pair of cylindrical bases to be inserted into the two holes. Those two bases are connected to a pair of airfoil resembling pillars that are exposed to the air and holds the front wing up. The front wing itself also resembles the shape of an airfoil and is supported up by two aerodynamic pillars, on either side of the front wheel skirts.

The back wing is joined to the main body in a very different way than the front wing. The two ends of the back wing are connected by an arch, much like an airline earphone, that spans across the top of the CO2 canister compartment. The arch is designed and manufactured precisely to the millimeter to ensure that the “headphone” arch fits into the engraved arch slot perfectly.

Both wings are produced by a 3D plastic CAM machine that builds the wings out of plastic materials through computer instructions and heated acrylic wires.

Tether Line Slot

The tether line slot runs through the center bottom of the car’s main body and features two tether line guides that keeps the tether line in and thus keep the car on the racetrack during the process of the race. As there is a relatively big space between the bottom of the main body to the racetrack, the tether line slot was also in turn elevated slightly based on the height of the race car base.